Home

Portfolio

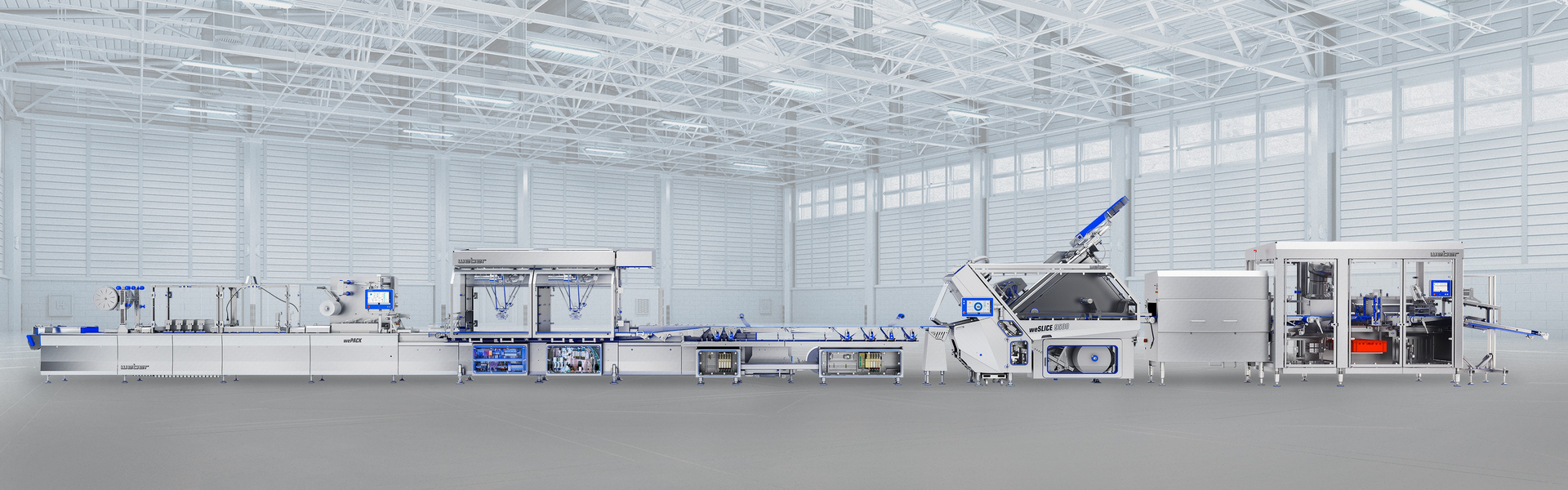

Intelligent solutions over the entire line.

Whatever you have to slice, we have the matching solution.

Whether it's sausage, ham, cheese, bacon or products made from vegetable proteins, every product category has its own challenges and every process phase its own Weber solution. Complete lines are just as much our strength as clever, individual, detailed modules. Your benefit by choose one partner, no matter the place on your production whether it be slicing all the way to packaging, you get everything from one source at Weber. This means all components are perfectly matched and communicate with each other throughout the entire process. We develop uncompromising concepts so that you do not have to make any compromises with regard to quality and efficiency.

Contact